Innovation & Technology

Working together for the world's most important industry

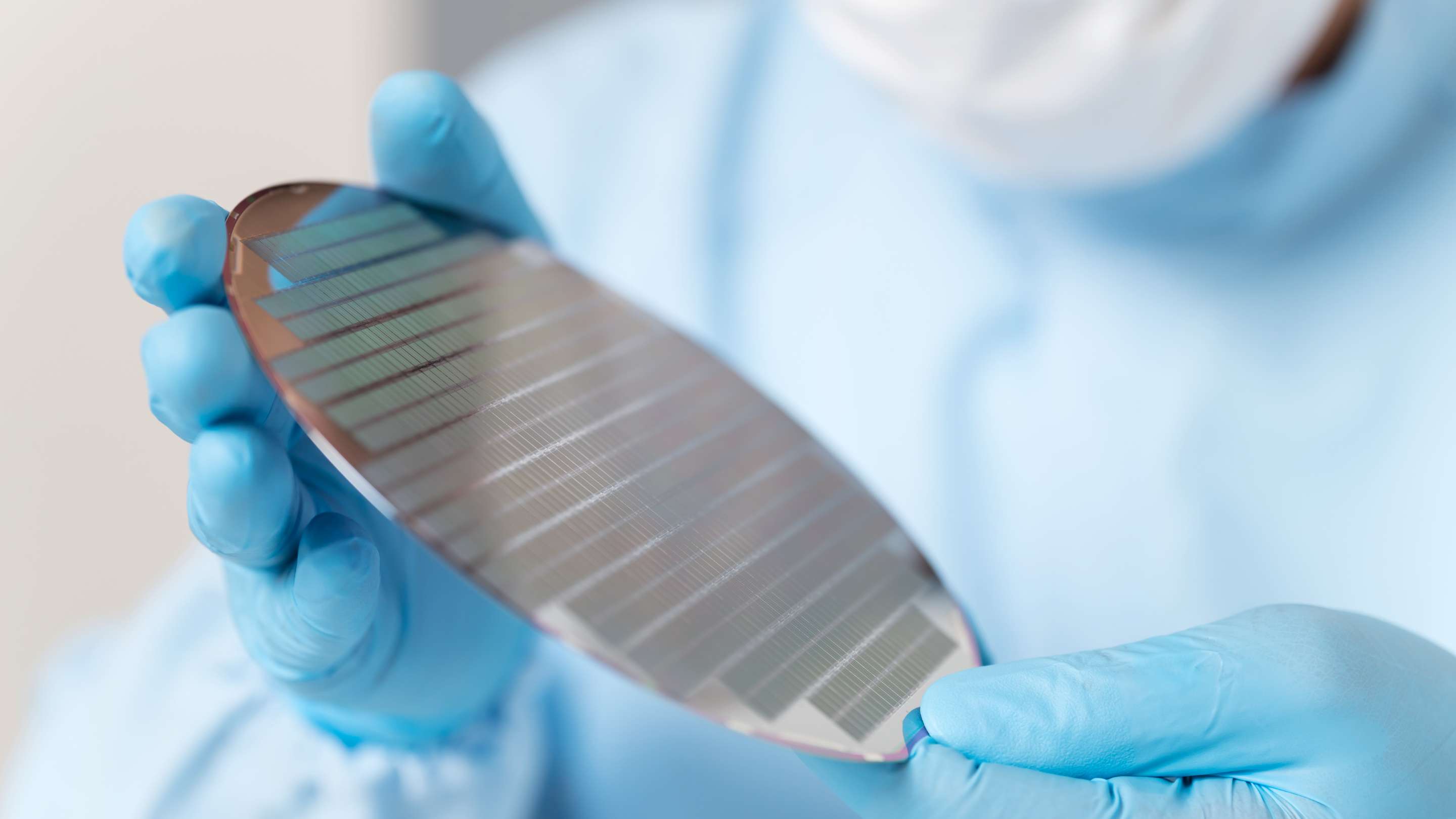

Semiconductors are the basic building blocks of our modern lives; no electronic device can work without them. Demand is huge - and will only continue to grow. We sat down with Jens Tempel, from FUCHS and Bernd Dötterl, from DMG MORI, to discuss how their companies want to jointly shape the market for the most important technology of the 21st century.

Semiconductors are the basic building blocks of our modern lives; no electronic device can work without them. Demand is huge - and will only continue to grow. We sat down with Jens Tempel, from FUCHS and Bernd Dötterl, from DMG MORI, to discuss how their companies want to jointly shape the market for the most important technology of the 21st century.

“FUCHS’ business is based on its knowledge of lubricants. And this knowledge can be transformed into logics. Logics that can be used to predict the behavior of a lubricant in a customer’s planned application, for example.”

Dr. Matthias Marquart, Chief Digital Officer, Fuchs Petrolub SE

Fine cutting oils of the highest quality

Mannheim · 01.08.2021

The internationally active company FEINTOOL with its headquarters in Switzerland is the market leader in the field of fineblanking. This process is used to produce high-precision components from strips and sheets, for example for drive trains in vehicles. The demands on production and thus on the necessary lubricants are constantly increasing, partly due to the growing complexity of the parts. Together, FUCHS and FEINTOOL have developed oils that are as powerful as they are tailor-made - and ensure the quality of the components.

DMG MORI and FUCHS - two powerful partners

DMG MORI, the leading global manufacturer of machine tools, and FUCHS have been closely linked for years as technological leaders. Working together, the partners set new standards in the field of machine tool lubricants with innovative product developments.

Learn more aboutCustomized lubricants for electric vehicles

FUCHS BluEV is a new all-in-one product line that includes lubricants, thermofluids, and specialty fluids for the mobility of the future. The success of the product launch in Shanghai underlines the gap in this booming market, which was clearly waiting for products of this kind.

Learn more aboutCar of the future: a calm and peaceful interior

Trends like e-mobility are presenting the automotive industry with new challenges. After all, the silence that results from not having an internal combustion engine not only changes the nature of mobility, but also the perception of the familiar background noise in vehicle interiors.

Learn more aboutThe future of aviation is easy – FUCHS flies ahead

·

Lightweight construction is the future of aviation. Because if you want to reduce the environmental impact of an aircraft, you have to lower its weight and thus its fuel consumption and CO2 emissions. This is made possible by carbon fibre reinforced plastics (CFRP) and glass fibre reinforced plastics (GFRP), which are 30 percent lighter than aluminium alloys. In order to make the wet machining of CFRP and GRP in particular efficient, FUCHS has developed a water-miscible high-performance cooling lubricant for wet machining: ECOCOOL GLOBAL S 240, which, like the cutting oil PLANTOCUT 22 SR, has just been approved by aircraft manufacturer Airbus for machining and drilling applications on components made of metal and CFRP. "Lightweight construction is a key technology for a sustainable future," says Executive Vice President Industry Division Dr Thomas Christmann of FUCHS. "With our solution, we are paving the way for the uncomplicated integration of new materials into established production processes."

Greases, the special kind of lubricant

The lubricant market is changing. Demand for highly efficient greases is increasing. With its new PU grease plant in Kaiserslautern – the largest of its kind in the FUCHS Group – the final piece of the puzzle has now been put in place for targeted supply of the entire market.

Learn more aboutSite advantage

A subsidiary of ZF Friedrichshafen AG in Shanghai needed to replace its cooling lubricant. A test of various candidates revealed the key moments involved in deciding on an alternative – and the fact that there's more to it than an excellent product.

Learn more aboutThe secret of global strength

Not all companies are made alike. One may operate solely in local markets while others move at a global level. Their needs differ. How can we cater to them all as a lubricant producer? It's a question of balance.

Learn more about“We now enjoy intensive exchange of knowledge, experience, and ideas at all levels of our two companies. As partners, this clearly makes us both stronger.”

Christian Thönes, Chairman of the executive board at DMG Mori Aktiengesellschaft

Racing for the future

Formula Student at the Hockenheimring gives budding engineers the opportunity to showcase their car-building skills. For FUCHS, this is a good reason to sponsor students. It’s a matter of investing in not only German engineering skills, but also the jobs of the future.

Learn more aboutBos up and running again – thanks to Carbaflo

There’s nothing better than being able to solve problems straight away. FUCHS LUBRITECH technical consultant Bernd Schneemann actually wanted to discuss the completion of a project. Just a regular meeting. But suddenly his expertise was required elsewhere, and FUCHS LUBRITECH was able to show that no special case is too special when you have the right solution.

Learn more aboutDig deep, fly high, go far

Companies with global operations not only face global problems but also the many local challenges of this world. The response to these challenges is: communication, cooperation, and concentration. With its "Global Research & Development Network", the FUCHS GROUP has created the right instrument for this.

Learn more aboutA small stove with a big impact

Since January 1, 2020, FUCHS has been a carbon-neutral company. As the group is unable to avoid all emissions, it compensates the remaining carbon emissions by purchasing climate certificates, contributing to sustainable development at various locations around the globe. Here's an example from Uganda.

Mehr erfahrenEcological vision: Along the entire supply chain

Sustainability and environmental friendliness are of particular importance at FUCHS. At its 60-some sites around the world, the Carbon Neutrality Strategy is already being implemented at FUCHS. Yet this is not enough for the company. The lubricant producer is looking far beyond its own boundaries at the complete process and supply chain of its products.

Mehr erfahrenEcolabel – the “blue angel” for international business

The days when products needed to be cheap above all else are over. Consumers today are primarily concerned with sustainability. In order to prompt trust in their own products, more and more companies are having them certified. FUCHS LUBRITECH recently received the EU Ecolabel for its release agents and greases. But what does a label like this mean for the company?

Mehr erfahren