There’s nothing better than being able to solve problems straight away. FUCHS LUBRITECH technical consultant Bernd Schneemann actually wanted to discuss the completion of a project. Just a regular meeting. But suddenly his expertise was required elsewhere, and FUCHS LUBRITECH was able to show that no special case is too special when you have the right solution.

Bernd Schneemann squints. Who would have thought that the sun would come back after the morning’s freezing fog? The automatic blinds close a little. Outside, despite the blue sky, it’s a frosty five degrees. An appropriate temperature for the middle of November. The atmosphere in the BOS meeting room in Ostfildern, on the other hand, is anything but frosty. Mr. Schneemann is currently discussing a successfully completed project with the managers of the automotive supplier and leading global manufacturer of roller blind systems and would like to move directly to the next point – when the door opens, and a BOS employee interrupts the conversation. It hasn’t worked again, unfortunately. The stone is still grinding directly on the profile. Critical looks toward the door. Apologetic glances at Bernd Schneemann. An annoying problem with a guide rail, which is unfortunately taking up a lot of their time at the moment. The sales engineer pricks up his ears. He’s sure that FUCHS LUBRITECH can help. “So, then I just asked what it was all about,” Schneemann explains later. “After all, we at FUCHS LUBRITECH like to have an ace up our sleeve for such special cases.”

BOS’

16.500 m2 production facility in Mexico has been operational since 1998.

Solutions for special cases

Within Mannheim-based parent company FUCHS PETROLUB SE, the world’s largest independent lubricant manufacturer, FUCHS LUBRITECH is responsible for specialty lubricants and release agents. These are products that have to meet extremely demanding requirements and thus, above all, the challenges of the various individual applications, such as extreme heat, high torques or other environmental influences. “It’s the same at BOS,” explains Schneemann. The technical consultant is in his element when his customers suggest that they take a look at the guide rail together. Because here at the BOS headquarters, the experts are working on mechatronics, kinematics and plastic systems. Virtually all major OEMs in the automotive industry are supplied by BOS. The company’s history dates back to 1910: a traditional family business that has grown into a global player over the last 100 years, with 21 branches worldwide and 150,000 square meters of production space. The main development site in Ostfildern is correspondingly modern.

“CARBAFLO 2160 is an all-rounder, and the best example of our special lubricants. No wonder that BOS immediately began using the paste in its series production,” says Bernd Schneemann.

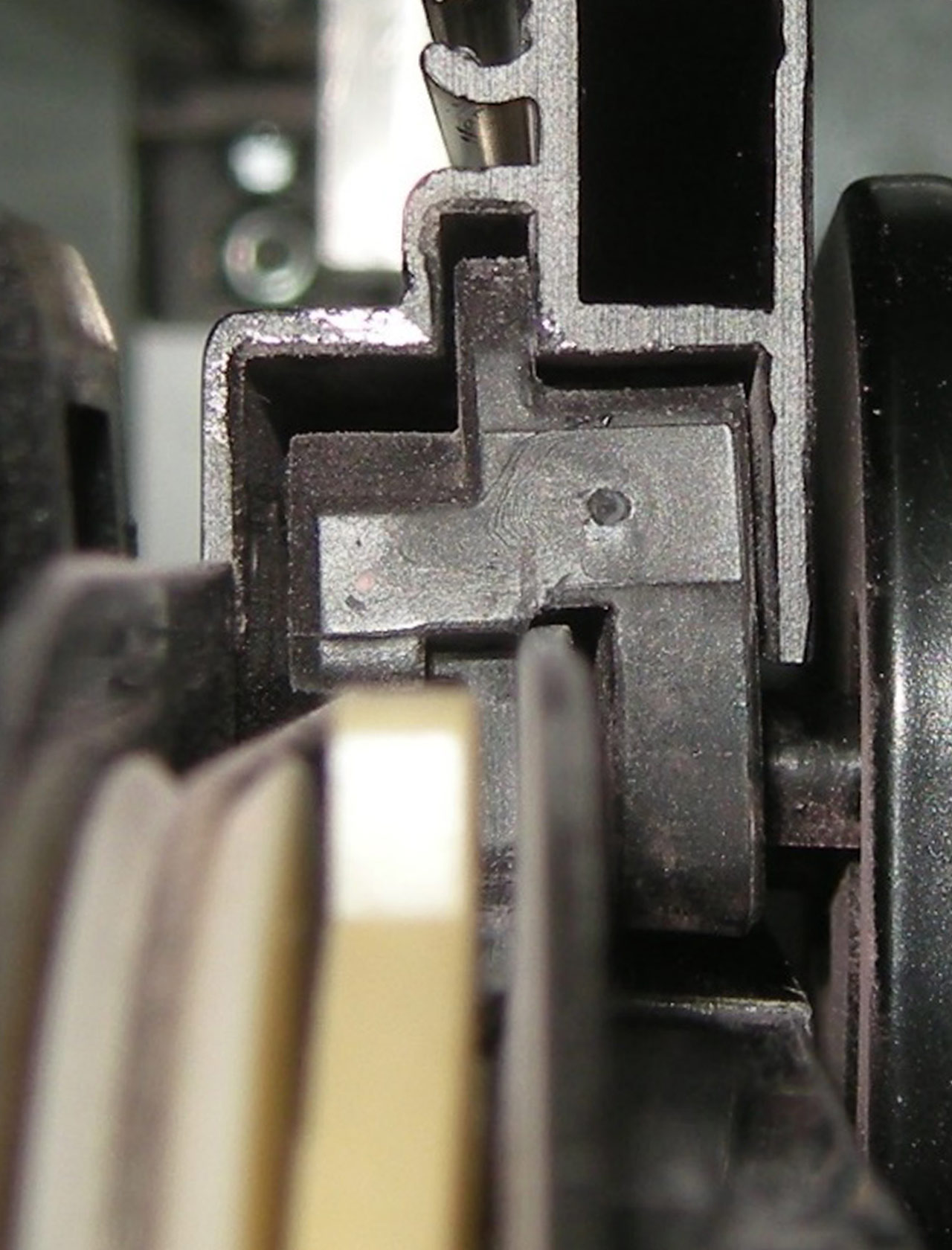

Problem: hardened dust

Together with the BOS specialists, Bernd Schneemann looks at the finished component – an electric roller cover for luggage compartments. The BOS employees explain to the FUCHS LUBRITECH sales engineer that a guide rail made of an aluminum profile with a plastic glider should run “dry” here. But when mineral fine dust gets between the glider and the running rail, nothing works anymore. The dust solidifies, hardens, almost turns to stone. The result – creaking and catching. The roller cover in the luggage compartment, which is supposed to glide forward almost by itself, catches and stops. The developers at BOS had already tried a few lubricants. However, these contaminated the rail even further, and made the sliding even worse. And there’s no sign of a solution. “The lubricant mustn’t react with other materials. Most importantly, dust shouldn’t pose any kind of problem,” says Mr. Schneemann, by way of summary. “There’s really only one product that has these exact characteristics: CARBAFLO 2160.”

Electric cover blind for luggage compartments: A guide rail made of an aluminum profile with a plastic glider has to to run dry here.

Fine mineral dust gets between the glider and the guide rail. The result: creaking and sticking.

The ace up the sleeve

CARBAFLO 2160 has excellent oxidation stability. It is also chemically inert and is not affected by metalworking or coating chemicals. In this particular case, this means that the white, almost transparent high-temperature paste doesn’t mix with corrosive dust and thus prevents creaking noises. The stick-slip effect does not occur. When used correctly, CARBAFLO 2160 guarantees lifetime lubrication of sensitive slide rails and adjustment mechanisms, such as in sliding roofs – or even in roller covers for luggage compartments.

“I then sent a sample and right from the first test it was clear that CARBAFLO 2160 was perfect,” says Schneemann. So perfect that only two months later this anti-creak paste was being used in series production at the BOS production facility in Mexico. “That was quick, but I don’t think I know of any other lubricant that could convince customers so quickly of its applicability and versatility,” says Schneemann. “In CARBAFLO 2160, BOS has a lubricant that can be applied anywhere and, above all, used sustainably.” A nice bonus: The success of this project subsequently led to an even closer customer relationship between BOS and FUCHS LUBRITECH, giving BOS access to the FUCHS LUBRITECH experts’ specialist knowledge in the field of special lubricants. The result? A sustainable technology partnership with a focus on unique challenges and their solutions.