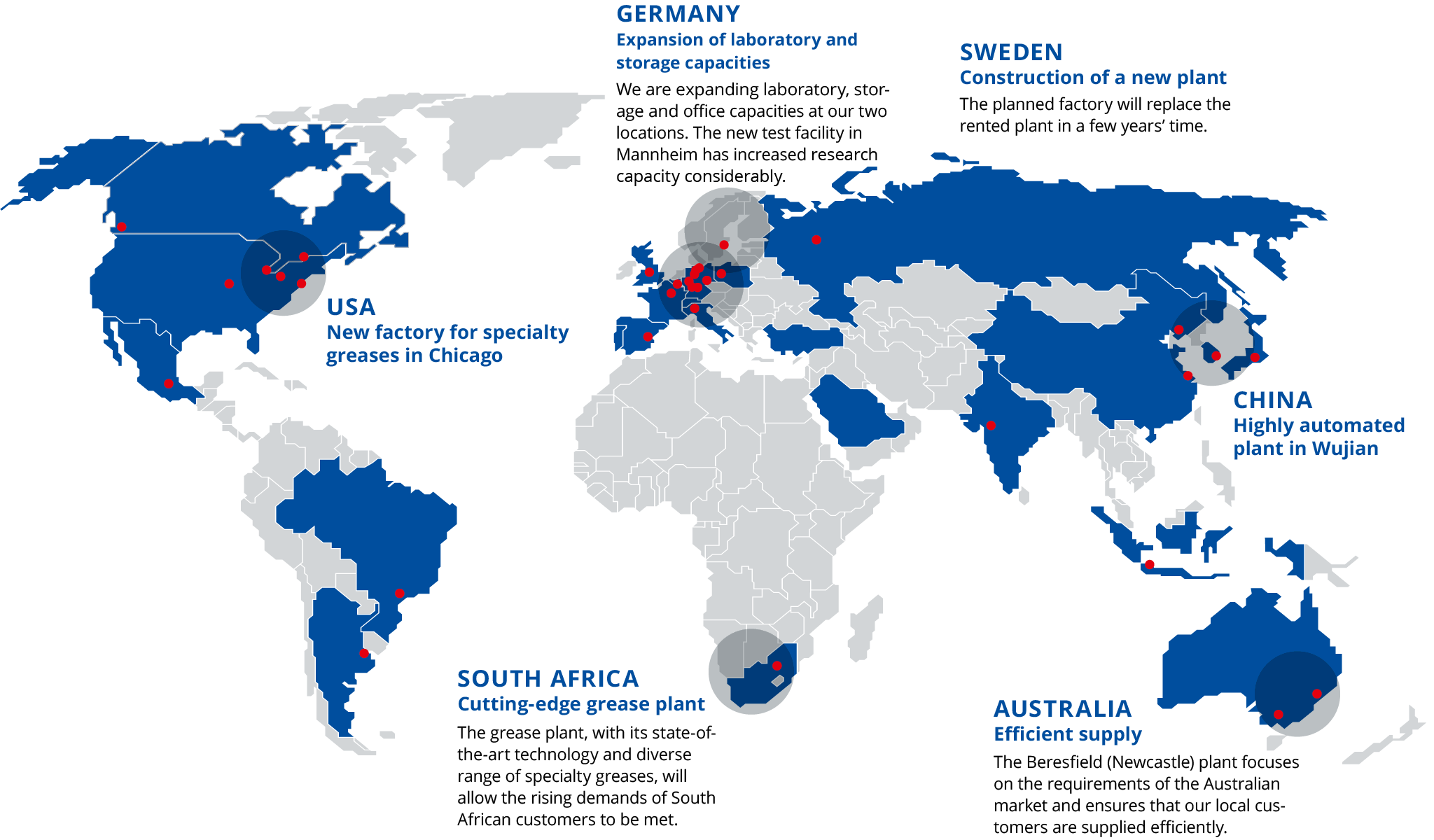

Close to the customer all over the world

Our company can be found wherever our more than 100,000 customers need us – in over 45 countries around the globe. We have local bases with our 58 operating companies and 33 plants. And, as part of its growth initiative, FUCHS is continuing to invest in building new locations and expanding existing locations worldwide. At the same time, our employees work closely with their international colleagues. This connected, extraordinary know-how and our employees form the basis of our success.