The world is becoming ever more complicated. As a supplier to industry, it's no longer enough simply to offer individual products. Solutions are needed for ever more complex challenges. FUCHS is responding by realigning its organization into business segments. In this way, the solution provider is taking the complexity out of lubricant supply for its customers. An example: the cement industry.

“With the Cement business segment, we are most likely leading the way in terms of customer proximity and reducing complexity, says Klaus Holz, Head of the newly created “Cement” business segment at FUCHS. And he adds: “The challenges in a cement factory are simply very big. They require virtually every type of lubricant there is – from engine oil for motor vehicles in quarries to heavy-duty greases and oils for mills or furnaces.”

So it's understandable that efficiency is likely to be an issue. Holz claims that it's basically the same in all other industries, too. Whether in mining, the automotive or food industry – since 2020, FUCHS has divided the markets into what it calls segments, and serves these in very specific ways. This segmentation is therefore an essential part of the new FUCHS2025 business strategy. The change of perspective that this has brought about means that the global lubricant specialist now offers its customers not just individual products, but instead takes all their lubricant needs into account – and is therefore able to radically simplify lubricant management.

Extreme conditions for lubricants

But let's get back to the cement industry. It plays a special role within the FUCHS Group. Although we don't make our biggest profits here, we have been market leader in many applications for decades – for example when it comes to the open gears on tube furnaces, which are more than 100 meters long. FUCHS entered into the cement industry with its development of CEPLATTYN in the 1960s. This lubricant helps to mitigate the heavy wear in open gears. Today, FUCHS is the market leader for these highly efficient lubricants in the cement industry.

Within the FUCHS Group, even back then one of the deciding factors in achieving this market leadership was the art of enabling lubricant and machine to work perfectly together under the given conditions. And in the cement industry, these conditions are especially tough. The most important raw materials for producing cement are limestone and clay – rocks that are extracted by blasting and cracking with heavy machinery. They are processed further by crushing, milling, and firing. All equipment involved works under extreme conditions such as heavy vibrations, extreme temperatures, and high exposure to dust. Holz is convinced: “In a cement factory you can find virtually the complete spectrum of challenges that lubricants need to overcome.”

“In a cement factory you can find virtually the complete spectrum of challenges that lubricants need to overcome.”

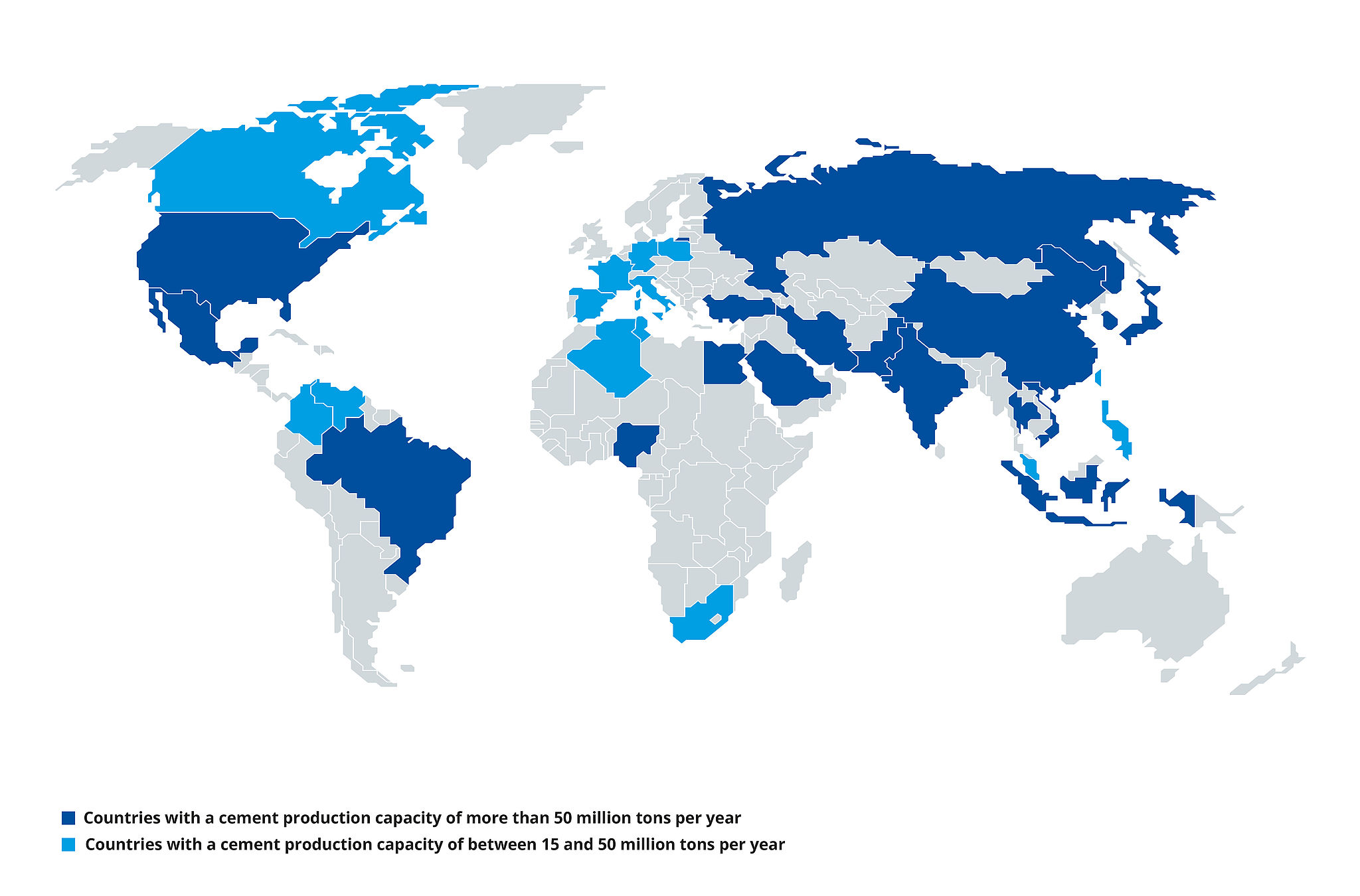

“Where we're needed, we're there” – Fuchs cement production worldwide

High complexity in lubricant management

It is for precisely this reason that management of the lubricant supply is so complex for cement producers. By simplifying this task, we can significantly improve time and cost efficiency and make life much easier for the customer. And it's no different in other industries.

A supplier can only meet these requirements by offering a comprehensive range of lubricants and services. “Indeed, we are increasingly asked to fully supply cement plants,” reports Holz. “This includes not just lubricants, but also services such as training, software, on-site service, oil analyses, etc.” All services that FUCHS has always provided. Since the Cement business segment was founded at the start of 2020, however, the lubricant producer has been offering them from a single source as a complete package.

Segmentation: Simplicity by looking at things as a whole

With its segmentation, FUCHS is now looking at all of its customers' lubricant requirements as a whole. “In the cement industry, for example, we previously focused on offering the cement producer individual special lubricants for individual applications in the cement plant. We concentrated here on the areas of heavy load, open gears, or high temperatures. The lubricants for other applications often came from other manufacturers.” As for lubricant management, this means that the cement producer has to talk to several contacts. Even at FUCHS, there were different contacts for different products.

This changed with the foundation of the “Global Business Segment Cement”. Applying the "One Face to the Customer" principle, a single contact at FUCHS now provides the customer with all the products they need for their plant. “When you come to think of it, we've always provided the full range,” says Holz.

Further improvement through services

Services have been part of the FUCHS sales mix right from the start. Valued throughout the industry for their excellence, the Cement segment offers exactly the right ones for every customer. Highly qualified technicians and more than 25 engineers visit plants in every part of the world, measure vibrations and temperatures, perform infrared analyses, and use the latest lubricant analysis tools to optimize lubrication at the plant. This leads to lower consumption, longer lubricating intervals, and longer service life for the machines.

In the specific case of one cement customer in Germany, the plant was able to cut lubricant-related costs by more than 30 percent thanks to an audit by FUCHS and consistent implementation of the recommendations.

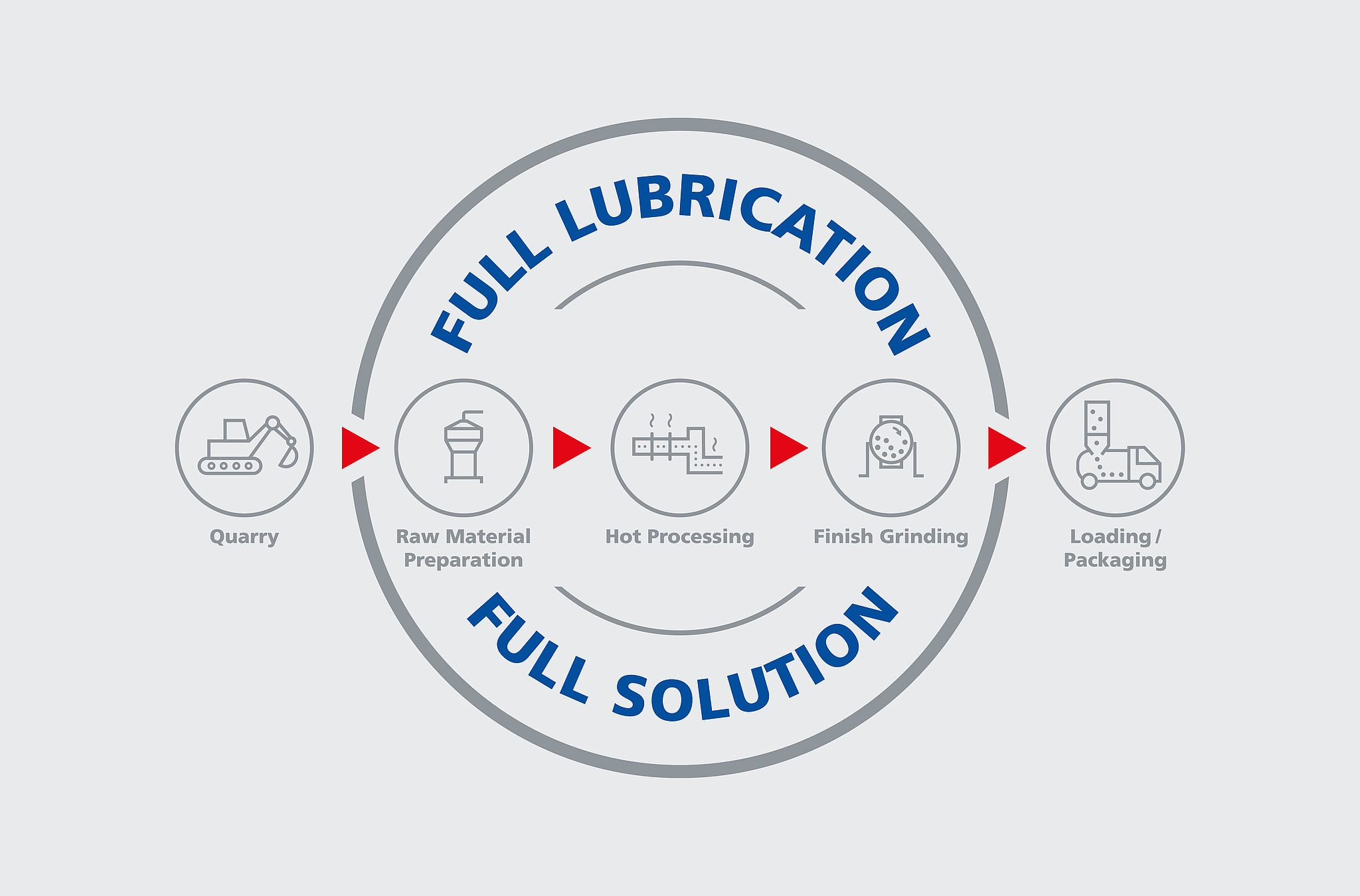

“Full Lubrication, full Solution”

Limestone and clay are mined in quarries as raw materials for cement. They are then processed in crushing plants, mills, and furnaces. The finished cement is stored in silos and finally loaded onto trucks, ships, or transport carriages for transport. FUCHS offers the right lubricants and services for all applications in this process from a single source.

A trump in terms of sustainability

Efficiency is not the only factor. Pressure on the industry to minimize its carbon emissions has grown enormously, both socially and financially. The industry is responsible for up to 8 percent of worldwide carbon emissions, and every ton of the greenhouse gas emitted costs money for certificates. One solution to this problem lies in using the latest lubricants. “For instance, we offer the latest gear oil with a very long service life. This reduces the amount of lubricant by up to 80 percent and energy consumption by up to 5 percent,” explains Holz. The potential of lubricants is equally important, such as for excavators in quarries. Together with BASF, FUCHS proved in a study that the diesel consumption of an excavator can be reduced thanks to improved hydraulic efficiency by using a high-grade hydraulic oil in comparison with a standard oil. With an observation period of 8,000 operating hours for the excavator, this equates to a carbon equivalent of around 30 tons. 2,400 beech trees would have to grow for one year in order to capture this amount.

Of course, using high-grade lubricants also has this effect in all other industry segments. Whether in state-of-the-art high-speed trains, wind turbines and hydroelectric facilities, or cooling circuits: Lubricants reduce friction, wear, and corrosion. As such, they guarantee sustainable and climate-friendly industry. For FUCHS, this is a goal of its corporate conduct, and not just for its customers. Since 2020, the lubricant specialist's production has been carbon-neutral from gate to gate. The FUCHS2025 business strategy is setting new goals in this field, too: carbon neutrality from cradle to gate by 2025.

The raw material is ground in vertical mills. The critical parts when it comes to lubrication are the bearings of the grinding rollers, the separator bearings, and the gearbox. They are exposed to extremely heavy vibrations, high temperatures, and dust. (source: Gebr. Pfeiffer SE)

Excavators and trucks work in very harsh conditions in quarries. Vibrations, dust, and environmental conditions are the greatest challenges for the lubricated parts.

“We have taken the step from local concentration on sectors like automotive, mining, industry, or specialties toward a segmented view of the market. As such, we no longer see the world exclusively in terms of products, but rather recognize customer requirements in a more integrative way and cater to them accordingly.”

Market segmentation – a foundation of the FUCHS2025 business strategy

Whether global customer requirements, new digital business models, or megatrends like e-mobility and driverless vehicles – the lubricant industry faces new challenges. The FUCHS2025 business strategy was conceived in order to turn these challenges into opportunities for FUCHS. The Group's goal in pursuing this strategy is to be the first choice for lubricants, everywhere and every time. One of the key elements of this strategy is market segmentation, which results in a comprehensive view of customer needs. To achieve this, the Group has divided the market into global segments that can be served worldwide. They include the automotive sector, the food industry, glass production, mining, or cement production. In these segments, customers are served according to the “One Face to the Customer” principle, so that they have a competent and comprehensively informed solution partner available for all their lubricant needs.

How FUCHS makes life easier for entire sectors

Dividing the market into global segments brings FUCHS and its customers many benefits. The international segment managers explain what exactly these are.